CONSTRUCTION of the RX19

********

LIST OF COMPONENTS

Active

IC1 MC3362P

IC2 MC145170P

IC3 MC68HC711D3FN (to be programmed by the author)

IC4 NM93C0N

IC5 MC34064P

T1 J310 TO92

T2 BC859C SMD

T3 BC859C SMD

Resistors SMD (1206 unless indicated)

Capacitors

R1 1 kohms

C1 15 pF* NPO 805

R2 100 ohms

C2 100 pF 805

R3 12 kohms

C3 12 pF* NPO 805

R4 12 kohms

C4 0.1 µF mc/2.5

R5 150 kohms

C5 100 pF NPO 805

R6 12 kohms

C6 22 pF NPO 805

R7 1 kohms

C7 0.1 µF 1206

R8 1 kohms

C8 0.1 µF 1206

R9 3.3 kohms

C9 0.1 µF 1206

R10 100 kohms

C10

220 pF NPO 1206

R11 39 kohms

C11 0.1 µF mc/2.5

R12 3.3 kohms

C12 22 nF 805

R13 10 Mohms

C13 0.1 µF 1206

R14 2.2 kohms

C14 47 pF* NPO 805

R15 120 kohms**

C15 0.1 µF

mc/2.5

R16 2.7 kohms

C16 47 pF 1206

R17 33 kohms

C17 1 µF pt/35V

R18 à R26 390 ohms / 805

C18 22 µF pt/10V

R27 12 kohms/ 805

C19 220 pF 1206

R28 10 Mohms

C20 10

µF pt/10V

R29, R30 33 kohms/ 805

C21 27 pF NPO 805

R31 12 kohms/ 805

C22 27 pF NPO 805

R32 à R34 33 kohms/ 805

C23 0.1 µF 1206

R35 56 kohms/ 805

C24 0.1 µF 1206

R36 47 kohms/ 805

C25 0.1 µF 1206

R37 et R38 56 kohms/ 805

C26 22 ou 33 µF CMS/10V

Caj 22

pF pas de 5

* Pour le 41 MHz : C1=18 pF C3=18 pF C14=68 pF

* For the 41 MHz: C1=18 pF C3=18 pF C14=68 pF

** adjust according to the need of the AGC

805=item size 1206=item size

Others

1 set of special coils L1, L2, L3 and L4 (author)

1 set of printed circuit boards (possibility to group orders)

1 case + decorative decal

1 quartz 10.7 filter MHz, kind like XF106 (Lextronic)

1 ceramic filter CFW455G (Lextronic)

1 quartz 10 MHz in a case HC49/S (from Radio Spares)

1 quartz 10245 kHz, type RX16 (MATEL)

1 PLCC socket SMD 44 pins (RS)

1 block of 4 dip switches ITT CDB4LS (RS)

1 female connector 2.54, 5 pins (RS)

1 32-pin connectors 2.54 (RS)

5 screws of 1.6x10mm, milled head

1 brass nut 1.6mm

Flexible wire for interconnections and antenna

NB. Contact us for any problem of supplies.

Possible bulked orders of parts

2. PREPARATION

Assemble all components, the printed circuit boards, and the case. Proceed to the

cutting of the holes for the connectors.

Best is to use the decoder plate as a gauge. The female connector Conn1 must be embedded

in its cutout space.

The grooves cut in the PCB must be tight fitting, for a good stability of the synthesis.

Tap the five holes to a diameter of 1.6mm.

For the HF module, add a nut welded to the back: screw the nut on a screw of 1.6mm, screw

this screw in the plate,

bring the nut in contact with copper and solder it in place.

Soldering will be much easier if you sand the brass nut before. Remove the screw.

Do not install nuts on the corners of the decoder, but spacers of 6 mm out of brass,

aluminum, or plastic.

3. INSTALLATION OF COMPONENTS

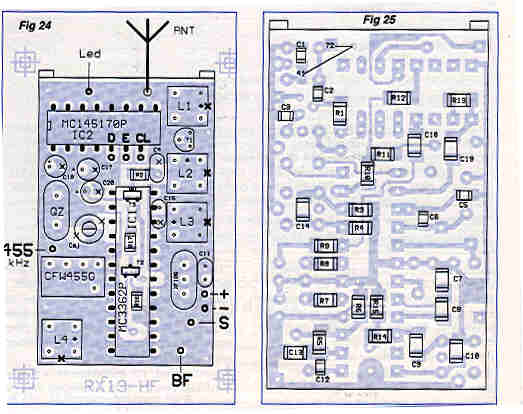

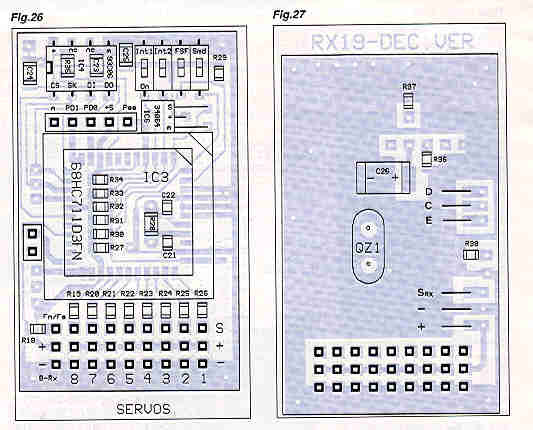

a) HF Part.

If the holes are not metallized,

install some jumpers front-to-back: under the MC3362 and the 145170. Solder T2, T3, R16

and R17 then R2, C4 and C15. Be careful, the installation of C15 is rather critical. You

will need a thin capacitor.The ground wire does not penetrate through the plate. Fold to

90° and solder it flat on the negative trace.

Take care not to touch pin 22 of the MC3362 and not to block the installation of the

shielding of L3.

You will place these components, temporarily, to check that all is well.

Finish installing the components on the topside and the rotor of Caj next to pin #3. Do

not apply excess solder on the back where SMD components will also be placed. Pin #16 of

the 3362 must be soldered to the negative trace if the holes are not metallized. Do not to

forget the test points, made from simple component leads. Sand the back. Clean with

acetone.

Solder all the components belonging on the back.

N.B. 1 we recommend the systematic measurement of the value of SMD

capacitors. They are not marked and a mistake is, afterwards, very difficult to detect.

N.B. 2 resistors R15 of the RX19 regulates the effectiveness of the

AGC. We can accept an initial value of 120 kOhms, with the recommended transistors.

Nevertheless, we would be able to adjust this resistance according to the following

criteria:

- Without a signal, R2 must deliver the maximum voltage towards T1. If the tension is

already lower, resistance is too large.

- Transmitter switched on with a 12 V light bulb in lieu of the antenna and a few meters

away from the circuit, the AGC must enter in action, lowering the output voltage from R2.

If the tension does not drop on a strong signal, resistance is too low.

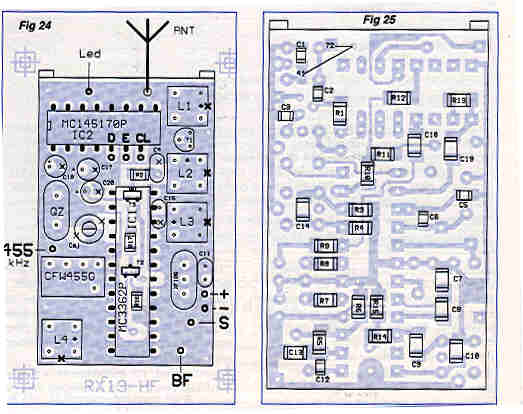

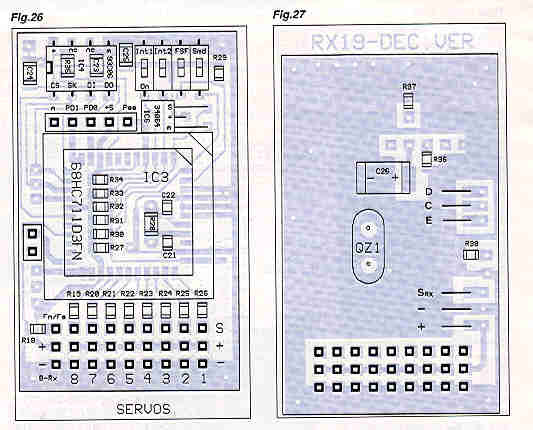

b) Decoder

Last version of RX19 is RX19B with a modified decoder :

>>>> RX19B

If the holes are

not metallized,

If the holes are

not metallized,

work is more delicate because it is necessary to install front-to-back jumpers on the

connectors Conn1, Conn2, and Conn3. Do that with

very fine wire soldered flat, on the topside, extending across the holes

at the same time as the pins. Install

a jumper also under the µC and another along the right edge. At the points of connection

of the servo wires, the male pins should go across the holes completely so to solder them

on both sides. Solder all SMD components

of the topside as well as QZ1. Then solder the PLCC socket, after having removed the

central part. Take care to orient it correctly. Put the pins in the correct place on the

circuit, and then fix the socket with 2 tacks of solder in diagonal.

Make a last check and it is all go

for the soldering of all the other pins. It is easy to guess that an iron with a very fine

tip and 5/10 solder are advised for this work. Once the solderings are made, check the

quality of work with a magnifying glass, then with the ohmmeter.

Finish the installation of the components of the topside. For IC4 and the switches do

not cut the pins that protrude.

They will be soldered front and back. Cut the others as flush as you can. They do not

protrude and should be soldered

on the front only.

4. STARTUP

a) Decoder

Check all work meticulously.

Put the DIP switches to OFF. Insert the µC in its socket. Prepare the powering on of

the decoder alone: battery connected through a switch on OFF. The 93C06 being blank, it

should be programmed to obtain the starting of the normal program.

For that, connect the point Pss of Conn1 to the negative trace and connect a voltmeter

between the point PD1 and the negative. Put the decoder under tension and note the change

of PD1 to 1 or +5 V. It is done, the 93C06 contains the data.

Put the switch to OFF. Remove the ground connection of Pss and remove the voltmeter.

Connect the oscilloscope on a

servo channel output and put under tension. Observe a 1.5 ms ridge on outputs 1 to 7 and

of 1 ms on output 8.

It is good, the decoder works. If you are curious, you can also check the existence of the

signal on Data, Clock and Enable.

b) Receiver

Connect the two PCB’s using two cords of three twisted wire of 5-cm length

approximately.

We always bring the HF module in service cups in place, not glued, without the shielding.

Screw L1, L2, L3 and L4 coils’ cores in a little but not completely, using the

appropriate tool.

Power up, put the oscilloscope between "Led" (fig. 24) and the negative trace.

Adjust L3 to have a base line at the high level, with very fine negative impulses, to 5

kHz.

If that does not work, check:

- The arrival of Date, Clock and Enable signals;

- The possibility to adjust VCO by L3 on the frequency necessary, i.e. 61550 kHz in 72 and

30400 kHz in 41 MHz;

- The existence of 10245 kHz on pin#2 of 3362 initially and on 145170 after;

- The integrity of the input connection of 145170 (R9, C16) and of output (R10 with R12,

C15 and C17).

All that to prevent the worse which only happens if you have badly worked!

The synthesis functioning, connect the oscilloscope between "BF" (fig. 24) and

the negative trace where one must

observe the usual curve to be set to the maximum through L4.

Put the SUPERTEF under tension, programmed on Fn = Fs = 72250 or 41100 kHz and a code

of "86".

Replace the antenna with a 12V/0.1A light bulb. The signal should appear. Adjust to the

highest value using L4 to about

800 mVcc. The future connected servos must answer (simply check the signals with the

oscilloscope).

If the adjustment of the transmitter’s frequency is correct, measure the 455 kHz at

the point "455" (fig. 24).

Adjust FI2 to this value using Caj. Re-adjust L4. Lastly, move the transmitter away until

having a rather strong curve on

the oscilloscope. Adjust L1 and L2 to reduce this curve as much as possible.

Determine if necessary the right value of R15. See Note#2.

5. LAST ADJUSTMENTS

See

also HOW TO ADJUST THE RECEIVERS.

Glue the cups with araldite. Place the shieldings one leg removed and solder the other.

Install the PCB’s in their casing.

Place a thin and hard insulator between the bottom and the HF part.

Re-do all the adjustments of the RX19, like above.

For L3, we program the SUPERTEF on the two limiting frequencies of the band and we adjust

this coil to have the same quality of impulse as measured on "Led" with the two

frequencies.

The balancing of L1 and L2 is done on the middle frequency of the band.

Fine tune the 455 kHz using Caj and finish by the final adjustment of L4. Glue the cores

permanently with wax.

6. USE

a) Initial programming.

To be done at the first startup or re-do if necessary:

- Temporarily connect Pss (PC7) to the negative trace

- Switch on the RX19

- The line PD1 indicates 1 when the programming of 93C06 is complete

- Turn the RX19 OFF and ON again. It uses the following data:

Fn = Fs = 72250 or 41100 kHz

PPCM code = 86

Channels 1 to 7 = 1.5 ms

Channel 8 = 1 ms

Average impulse = 450 µs

b) Programming RX19 by SUPERTEF

This can be done using a direct cable or an IR system.

IMPORTANT: press on the button BEFORE the powering up of the RX19. Keep pressing while

powering up.

Line PD1 indicates 1: The RX19 awaits data.

Send the data while following the instructions of the screen of the SUPERTEF. Line PD1

returns to 0. Disconnect.

Switch off the RX19.

Switch the RX19 on again for it to use the new values of Fn, Fs and Code

c) Programming of the average impulse

This adjustment makes it possible to optimize the sorting of short and long impulses of

code PPCM.

Place DIP switch1 (PC6) and DIP switch2 (PC5) in ON position.

SUPERTEF must emit a signal whose code contains, in binary, FOUR " 0 " and FOUR

" 1 ", for example " 86 " which is written as " 01010110 "

or " 170 " which is written as " 10101010 ". The RX19 is programmed on

this code and it receives indeed the signal which activates the servos. The RX19 must NOT

be on FAIL SAFE! Temporarily connect PC7 to the negative trace, with a push rod on Conn1

between Pss and the trace. Line PD1 indicates 1. It is done.

Switch the RX19 OFF and ON again.

d) Programming CONTROGAZ

Only turn DIP switch2 (PC5) to ON.

Proceed as in c) above except by positioning channel 7 (CONTROGAZ channel) on the desired

position.

Of course, to use the mode CONTROGAZ, channel 7 of transmitter must have for origin the

stick controlling gas,

therefore have an ORIGIN equal to 4 and the gas servo must be connected on channel 7 of

RX19.

e) Programming PROGRAM mode

Only turn DIP switch1 (PC6) to ON. Proceed as indicated in c) above but this time place

ALL the sticks in the position

you choose for the fail safe.

f) Configuration in flight

- Fail Safe

| DIP switch 1 (PC6 ) |

DIP switch 2 ( PC5 ) |

Fail Safe Result |

OFF |

OFF |

Nothing happens |

OFF |

ON |

CONTROGAZ |

ON |

OFF |

PROGRAM |

ON |

ON |

EXTERNAL |

- Direction of the modulation shift. By DIP switch

4 (PC3)

OFF: "Thobois" shift

ON: shift reversed

- Fail Safe Delay. By DIP switch3 (Pc2)

OFF: approximately 2.5 sec.

ON: approximately 1.25 sec.

- In flight:

Do not press on Pss

Buzzer alarm on PD1 by Conn1

If the holes are

not metallized,

If the holes are

not metallized,